0512-57906238

Tel:13656269491

Fax:0512-57906239

Mail:mef@micro-ef.com

Addr:No. 189, ZhangJi Road Kunshan City ,China

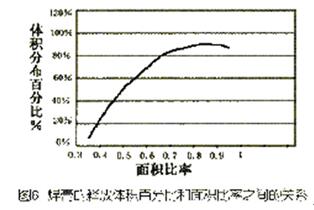

For the 0201 element, the opening area of the template is reduced as the size of the pad is reduced. This leads to a decrease in the area ratio. When the template design of 0201 components, a little problem is very important to note that, for the laser cutting template area ratio should be greater than 0.65; for the electroforming stencil area ratio should be greater than 0.6. Later, we will discuss why the area ratio of laser cutting templates is larger than that of electroformed templates. Here we have a diagram to show the relationship between the release volume, percentage, and area ratio of solder paste.

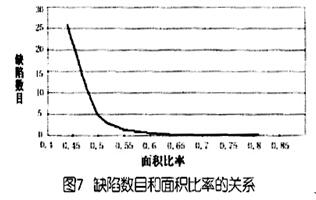

From this diagram, we can see that when the area ratio is greater than 0.7, the percentage of solder paste release volume is also higher than 80%, and when the area ratio is below 0.5, the release percentage is less than 60%. In the area ratio of 0.5-0.7, its release percentage is between 60-80%. The data were obtained from an electroformed template. When the area ratio is below 0.6, we can see that the deviation of volume ratio starts to increase rapidly. The reason for this problem is that at this point there are more openings or blocked openings. As more openings are blocked, this also results in an increasing number of defects in the 0201 component as the area ratio decreases. The following diagram shows the relation between the number of defects printed and the area ratio of the 0201 component printed with an electroformed template. (see Figure 7)

As can be seen from the diagram above, when the area ratio is greater than 0.65, the number of defects begins to increase near 0.625. At about 0.565 of the area ratio, the number of defects began to increase considerably.

Another problem in the 0201 manufacturing process is the choice of template type, that is, whether to choose an electroforming template or a laser cutting template. The laser cut template is drilled through the laser and then polished to remove the rough part of the hole wall. Electroforming templates are made by forming technology, which allows for very smooth pore walls, which is very beneficial to solder paste release. The main problem with electroforming templates now is that they cost 2-3 more than laser cutting templates. From the two templates in the 0201 component printing test can be late, the amount of electroforming stencil printing paste is higher than the laser cutting template. The release ratio of the electroformed template is generally around 85%, while the laser cut mode is between 70-75%. In the experiment, we found that the number of defects appearing in the laser cutting template is higher than that of the electroforming template. Therefore, the influence of all aspects, in production, if conditions permit, should be preferred choice of electroforming template. Electroforming templates are recommended in the 0201 element process.

Effects of 2 and 0201 components on patch equipment

Bonding is considered the most important part of the entire 0201 process. Since the mount system absorbs 0201 components from the feed system, visual only and accurate mount components, care must be taken in setting up this process. Basically, the 0201 mount process involves four separate actions:

A. from the first feeder drawing element. The most common, 0201 non voting components are wrapped on tape, and the pits are mounted on 8mm wide tape. When setting up the absorption process, you must pay attention to the details. Because 0201 is only the component of SMTI art since 1999, the error of production component and feed belt still exists. While on the belt it seems to be packed very closely, at the micrometer level, it is actually quite loose. Using a suction nozzle that is almost as big as a component, chances of aspiration may be high. For this reason, the suction nozzle is usually made a little larger than the element.

Once the B. is absorbed, the vacuum check determines whether the element exists or does not exist. This is an important aspect of the inspection, because if the element does not exist, the mounting head must be disposed of a non suction 0201 or re absorbing element. Error absorption generally does not directly affect the actual process, but will affect the total processing time and production. The present study also evaluated the difference between tape feed (tape-and-reel), Surf, tape, and final bulk box (bulk-case) feeding.