0512-57906238

Tel:13656269491

Fax:0512-57906239

Mail:mef@micro-ef.com

Addr:No. 189, ZhangJi Road Kunshan City ,China

1.20201 influence on printing process

In the process of SMT production, the printing of solder paste is usually the first step and the most critical process. Because statistics show that in the process of SMT production, 60%-70% welding defects are related to the printing of solder paste. In the printing process, there are several important aspects: solder paste, templates, printing equipment parameters. Here we mainly discuss the impact of the following 0201 on template design.

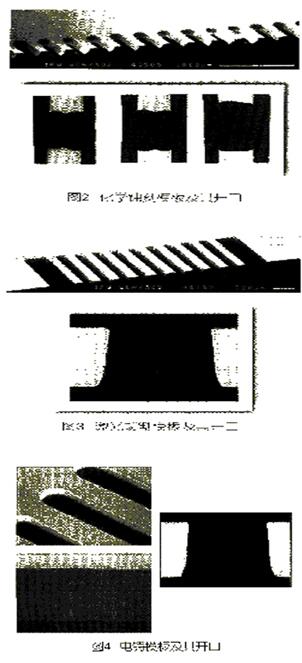

First of all, introduce three commonly used methods of template production: chemical etching, laser cutting, electroforming molding. The chemically etched openings are bowl shaped, release performance of solder paste is not good, and the opening is easy to plug, so it should be cleaned regularly, to template precision is relatively low, usually used for big element spacing 20miI, but its cost than the laser cutting and electroforming are low; laser cutting with laser template cut an opening on the ladder of nature, is conducive to the solder paste release, but not the hole wall of electroformed template is smooth, recommended for the element spacing less than 20MIL the price between the chemical etching and electroforming: electroformed stencil aperture is trapezoidal, rational and solder paste release, smooth hole wall very conducive to solder paste release, usually used for fine pitch and ultra fine pitch printing, with good wear resistance and long service life, the most expensive price in three weeks, making Longer period. This template is suitable for 0201 components. Here is a sketch of the three templates.

Two important parameters in the template are the area ratio of the opening and the width to thickness ratio. (see below) General requirements for a width to thickness ratio of >1.5, area ratio >0.65.